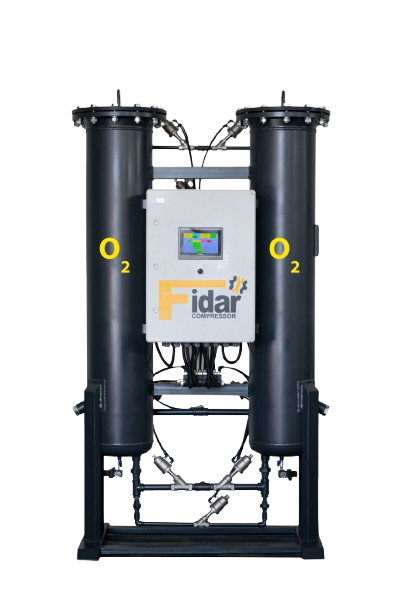

Oxygen Generator (PSA System)

What Is Oxygen?

Oxygen is an element in Group 16 of the periodic table, represented by the chemical symbol O₂.

It makes up 21% of the Earth's atmosphere and is the third most abundant element in the universe. Oxygen plays a critical role in combustion, respiration, and energy production. A large portion of the mass of living organisms is composed of oxygen.

Applications of Oxygen

-

Steel and metallurgical industries

-

Textile and fabric industries

-

Aerospace and diving industries

-

Medical and hospital applications

-

Glass manufacturing

-

Mining operations

-

Laboratory applications

-

Paper and cellulose industries

-

Fish farming and aquaculture

-

Ozone generation

Oxygen Production Methods

Oxygen is produced in both gaseous and liquid forms through two major technologies:

Capacity range: 3.2 Nm³/h – 216 Nm³/h

Purity: 90% – 95%

PSA Oxygen Generator

Oxygen generators manufactured by Fidar Faraz Fartak operate based on Pressure Swing Adsorption (PSA) technology.

In this method, compressed air—dried and filtered from oil, dust, and moisture—is fed into adsorption towers filled with Zeolite Molecular Sieve (ZMS). This adsorbent selectively captures nitrogen, argon, and other gases, allowing oxygen to pass through with a purity of 93% ± 2%.

How an Oxygen Generator Works

The oxygen generator is a twin-tower adsorption system, designed with:

-

Two alloy steel towers filled with ZMS

-

A complete filtration package

-

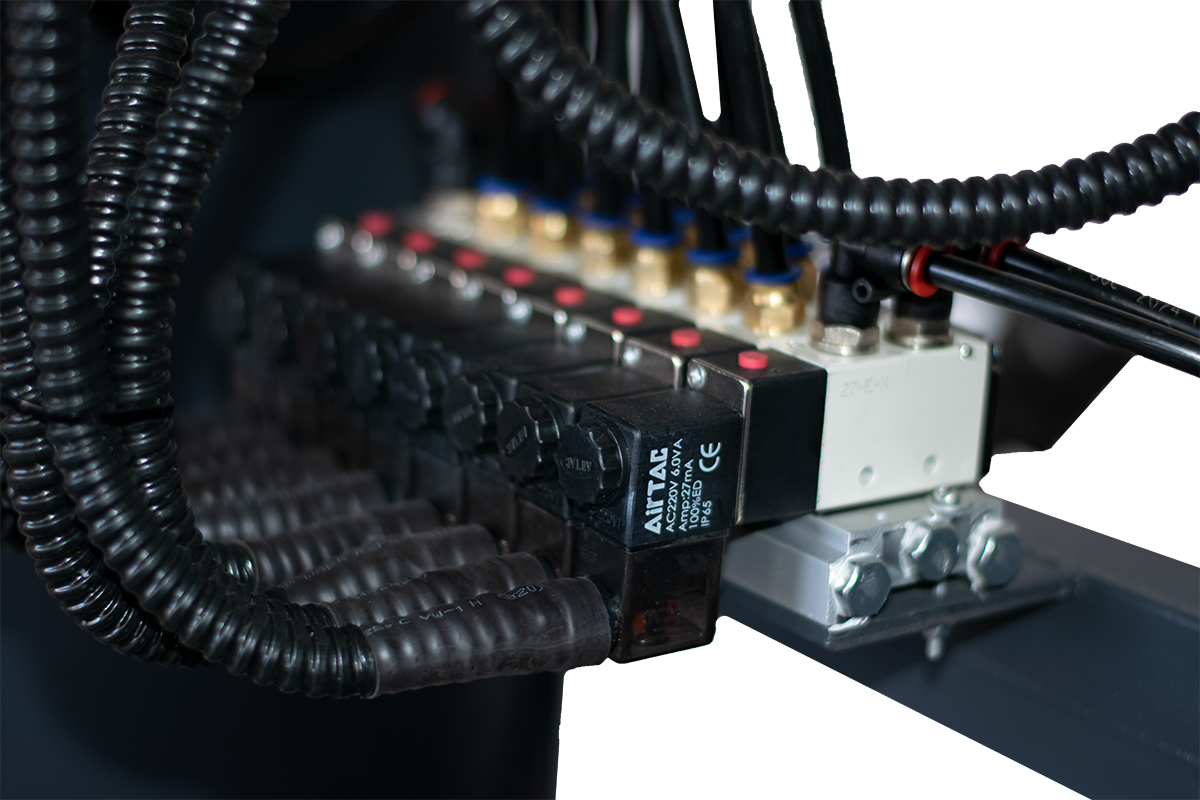

Pneumatic valves

-

Pressure regulators

-

Automated control components

Dry and clean compressed air enters one of the towers and passes through the ZMS bed. Due to the pore structure of the zeolite, nitrogen and other gases are adsorbed more rapidly than oxygen, resulting in a product oxygen purity of 93% ± 2%.

The oxygen produced at the top outlet is directed into an oxygen buffer tank, where the pressure is equalized before being delivered to the consumption line.

Key Features of Fidar Faraz Oxygen Generators

-

Simple and robust design with easy access to all components

-

Fully automatic operation with continuous 24/7 performance

-

Touchscreen display with real-time monitoring

-

High operational safety

-

Fast system start-up

-

Optional silencer system for ultra-low noise operation

-

Long-life pneumatic valves

-

Environment-friendly oxygen production with minimal operating cost

-

Adjustable output purity between 90% and 95%

-

Lowest consumable and maintenance costs in its class

-

Laser-type Zirconia oxygen analyzer with long service life

-

PLC-based intelligent control system

-

Equipped with pressure indicators

-

High-quality ZMS adsorbent from Xintao, with a service life of up to 5 years and 5-year warranty (under standard operating conditions)

For Technical Consultation and Pricing

Please contact our support and engineering team:

Phone: +982182802290

Email: info@fidarcompressor.com